INTRODUCTION FOR METAL STAMPING ESSENTIALS TOOLING, OPERATIONS, QUALITY, AND TROUBLESHOOTING

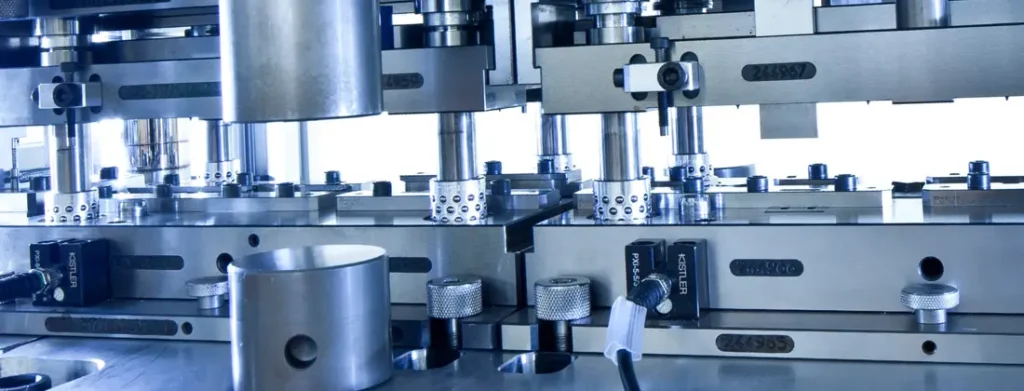

Metal stamping is a crucial process in the manufacturing industry, involving the shaping and forming of metal sheets into desired parts and components. This training provides essential knowledge and practical skills in metal stamping, from the basics of tool and die design to press operation, quality control, and troubleshooting. The course is designed to enhance employee proficiency, ensuring improved efficiency, safety, and product quality in metal stamping operations.

COURSE OBJECTIVES

- To develop foundational knowledge of metal stamping processes, tools, and equipment.

- To understand quality control principles and techniques in metal stamping.

- To equip participants with troubleshooting skills for common stamping issues.

- To provide quality assurance practices.

TRAINING OUTCOMES

By the end of this training, participants will be able to:

- Understand the fundamentals and applications of metal stamping processes.

- Identify and describe the functions of different types of dies and their components.

- Operate press machinery safely and understand essential operational parameters.

- Implement quality control techniques to maintain high product standards.

- Diagnose and resolve common metal stamping issues efficiently.

TARGET AUDIENCE

Includes entry-level operators, technicians, production supervisors, quality control inspectors, maintenance staff, and engineers in manufacturing roles who are looking to enhance their technical skills and understanding of metal stamping processes. This course is especially valuable for individuals responsible for maintaining production standards, ensuring operational safety, and troubleshooting common issues in metal stamping.

METHODOLOGY

Includes a blend of classroom lectures, interactive discussions, and case studies. Theory sessions are reinforced with Q&A, practical exercises, and knowledge checks, allowing participants to apply their learning in real-world scenarios.

TRAINING DURATION

| 2 days | 9.00am – 5.00pm |

COURSE CONTENT

Day 1: Fundamental of Metal Stamping and Tools & Die Basics

Introduction to Metal Stamping

- Overview of metal stamping processes and applications

- Key equipment and types of presses

Tool and Die Design Fundamentals

- Types of dies (progressive, compound, transfer) and components

- Basic die maintenance principles

Press Operation and Setup Basics

- Types of presses, setup, and calibration techniques

- Essential parameters: stroke, tonnage, shut height

Safety in Metal Stamping

- Machine safety, PPE, and emergency protocols

Introduction to Quality Control in Metal Stamping

- Common defects, quality control basics, and inspection techniques

Day 2: Quality Control, Troubleshooting and Practical Application

Advanced Quality Control Techniques

- Detailed analysis of defects, SPC, and inspection methods

Troubleshooting Common Metal Stamping Issues

- Identifying and resolving typical stamping issues (die wear, misalignment)

Press Operation and Die Maintenance

- Key maintenance practices and scheduling

Troubleshooting and Maintenance Workshop

- Practical exercises in troubleshooting and die maintenance

Summary, Q&A, and Final Assessment

- Recap of key topics, Q&A, and assessment to confirm understanding