LEARNING OBJECTIVE

- To provide fundamental knowledge of mould design principles

- To identify key components within a mould structure

- To increase awareness of tooling maintenance and troubleshooting aspects

WHO SHOULD ATTEND

- Moulding Technicians

- Production Engineers

- Experienced Injection Moulding Operators

- New technical trainees in plastic industry

TRAINING METHODOLOGY

- PDF notes/slides

- Worksheets & quizzes

- Sample mould drawings / 3D files

COURSE OUTLINE

DAY 1: Mould Design Essentials

Morning Session:

1.0 Introduction to Injection Moulding

- Types of moulding methods

- Basic process flow of injection moulding

- Role of moulds in determining product quality

2.0 Types of Mould

- 2-plate vs 3-plate moulds

- Hot runner vs cold runner systems

- Special moulds: stack and family moulds

3.0 Mould Component Breakdown

- Core & cavity

- Sprue, runner & gate (types and functions)

- Ejector systems (pin, blade, sleeve)

- Cooling systems

- Venting and air traps

Afternoon Session:

4.0 Basic Design Considerations

- Draft angle, wall thickness

- Parting line placement

- Shrinkage and warpage

- Suitable material selection for design

5.0 Design Flaws & Practical Examples

- Flash, short shot, burn marks

- Product defect analysis from moulding perspective

DAY 2: Tooling and Maintenance

Morning Session:

6.0 Tooling Material & Manufacturing

- Common mould materials (P20, H13)

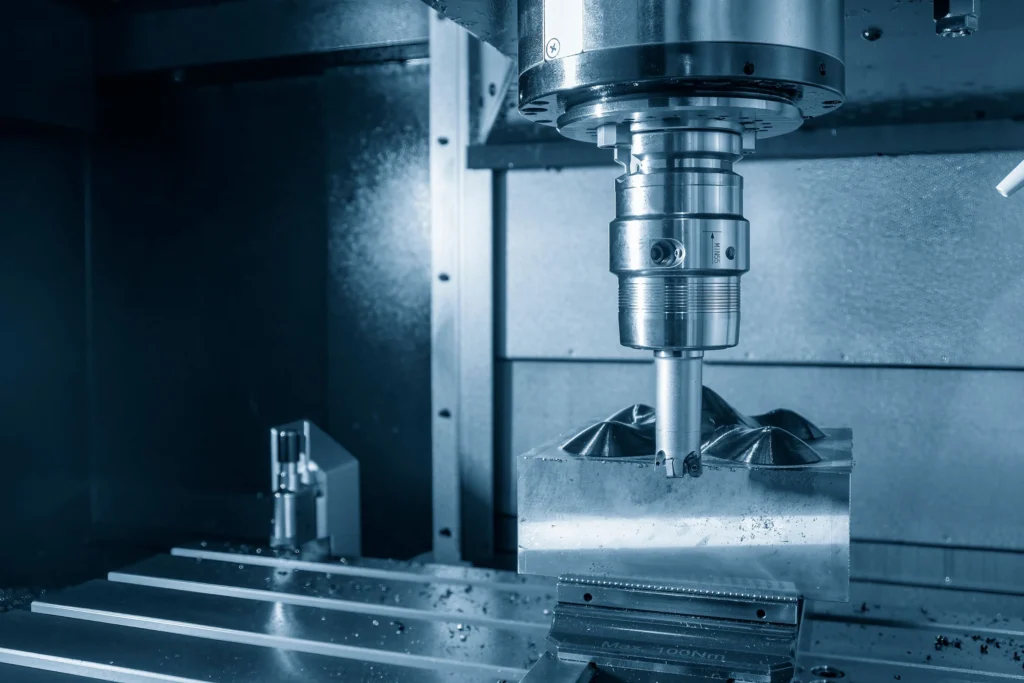

- EDM, CNC machining, polishing

- Surface treatments (nitriding, chrome plating)

7.0 Mould Assembly & Setup

- Mould installation on machine

- Safety precautions during setup

- Dry run and alignment check procedures

Afternoon Session:

8.0 Maintenance & Troubleshooting

- Preventive vs corrective maintenance

- Common moulding defects and tooling causes

- Cleaning, lubrication, and inspection checklist

9.0 Group Case Study

- Video or image analysis of real-case moulding problems

- Identify issues and suggest improvements

- Group presentations and discussion

Wrap-Up: Lessons Learned, Final Q&A, and Action Planning