INTRODUCTION NFPA 70E, STANDARD FOR ELECTRICAL SAFETY IN THE WORKPLACE (2018) TRAINING

These 2 days NFPA 70E – Standard for Electrical Safety in the Workplace (2018) training will provide the participants with sound knowledge and skills required in understanding the fundamentals of electrical safety in their daily job functions in line with NFPA 70E Standards 2018 and OSHA requirements.

LEARNING OBJECTIVE

To enhance knowledge and skills in the following areas.

- NFPA 70E, Standard for Electrical Safety in the Workplace (2018)

- Know what is NFPA70 and its governing clauses

- Explain why a safety program directed at electrical hazards is necessary and beneficial

- List the elements of a procedure for establishing an electrically safe work condition

- Identify required elements of a risk assessment and explain the difference between electrical hazards and risk

- Identify the information needed for shock hazard analysis

- Explain the intent and limitations of PPE prescribed by NFPA 70E

- Identify maintenance requirements for various types of electrical equipment and protective equipment

- Understand the fundamentals of electricity.

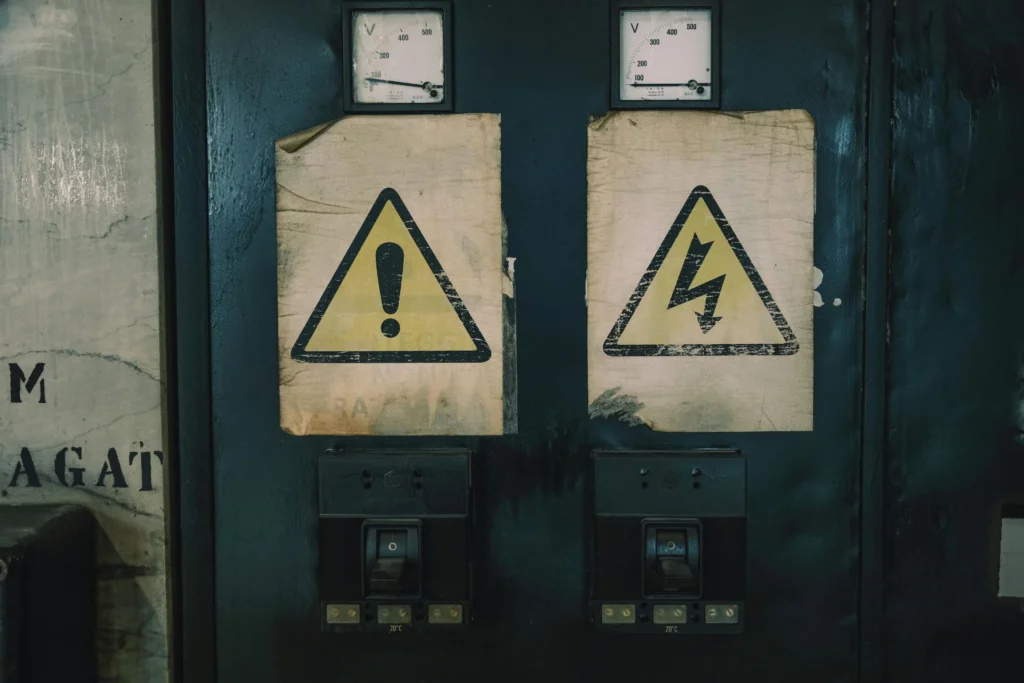

- Able to visualize electricity and its danger at workplace

- Understanding electric shocks and electric burns.

- Knowing the electrical safety model.

- Able to conduct and ensure zero energy present in electric circuit

- Know ways to recognize hazards.

- Understand all aspects of Personal Protective Equipment (PPEs)

- Understand risk evaluation.

- Knowing safe working environment.

- Able to work safely on live circuits.

- Know safe work practices.

- Direct and indirect costs to an employer from a fatal electrical accident

- Understand the application of NFPA 70E standards 2018 in all workplace processes and product builds in line with local legal requirement as per OSHA.

WHO SHOULD ATTEND

Electrical engineers, safety managers, electricians, electrical contractors, plant managers, facility maintenance personnel, electrical inspectors, risk managers, and project managers.

METHODOLOGY

The training will comprise 70% theory and 30% group discussions, Q&A session wrt NFPA70E and selected video clips to enhance learning.

COURSE OUTLINE

Day 1: Training topics

Pre Test Assessment

Introduction to NFPA 70E, Standard for Electrical Safety in the Workplace (2018)

Occupational Health and Safety Administration – OSHA

OSHA and Malaysian safety and legal requirements

NFPA 70E standards 2018 – Electrical safety

- Electrical Hazard Analysis

- Establishing an Electrically Safe Work Condition

- Working While Exposed to Electrical Hazards

- PPE

- Safety-Related Maintenance

- NFPA 70E: Electrical Safety in the Workplace

- Risk Assessment Procedure

- Hierarchy of Risk Control Methods

- Establishing an Electrically Safe Work Condition (ESWC)

- Exercise 2: Risk assessment procedure – Discuss.

Electricity and Its Danger

- Introduction to electricity and its safety

- Electrical Terminologies

- What causes an electrical shock?

- Exercise 1: List down all types of electrical danger including arch flash that is evident in your workplace.

Electricity and its associated dangers

Electrical Shock

- Severity of electrical shock

- Effects of Electrical Current on the Body

- Exercise 2: What is an electric shock? Discuss and share.

Electrical Burns

- Common injuries?

- Arc Blast Hazards

- Electrical fires

- Dos and Don’ts…?

- Exercise 3: Discuss on how to provide first aid for electrical burns.

The Electrical Safety Model

- Prevention – To Be Safe?

- Recognizing hazards

- Risks and Evaluation

- Control hazards

Recognizing Hazards

- How do your recognize hazards?

- Inadequate wiring

- Exposed electrical parts

- Boundaries

- Power lines

- Insulations

- Grounding

- Overloads

- Wet and dry conditions

- Exercise 4: Electrical safety hazards at workplace. Discuss to share.

Evaluate Risk

- How Do You Evaluate Your Risk?

- Conditions that point to electrical hazards

Safe Working Environments

- How Do You Control Hazards?

- How Do You Create a Safe Work Environment?

- Lock Out and Tag Out Circuits and Equipment

- Control Inadequate Wiring Hazards

- Control Hazards of Fixed Wiring

- Control Hazards of Flexible Wiring

- Use the Right Extension Cord

- Control Hazards of Exposed Live Electrical Parts

- Control hazards of shocking currents

- Control Overload Current Hazards

- Exercise 5: Line visit and Audit – What are considered as safe working practices against electrical injuries?

Day 2: Training topics

How to work on Live Circuits

- When You Must Work on or Near Live Circuits

- Live-work permit system

- Safe Work Practices

- First aids and Safety man

- CPR – Electricity danger and emergency

- Exercise 6: Electric current cannot be seen, cannot be heard and cannot be felt? Discuss the truth of the danger based on human senses and other test methods.

Safe Work Practices

- How Do You Work Safely?

- Plan Your Work and Plan for Safety

- Avoid Wet Working Conditions and Other Dangers

- Avoid Overhead Power lines

- Use Proper Wiring and Connectors

- Use and Maintain Tools Properly

- Exercise 7: List down all safe working disciplines one must follow to safeguard from electrical danger?

NFPA 70E standards 2018

- Risk Assessment Procedure

- Hierarchy of Risk Control Methods

- Establishing an Electrically Safe Work Condition (ESWC)

- Estimate of the Likelihood of Occurrence of an Arc Flash Incident

- Selection of Arc-Rated Clothing using Incident Energy Analysis Method

- PPEs

- Exercise 8: Discuss in your group and list down all electrical related safety PPEs used and its specific purpose in your workplace.

Arc Flash strategic plan Discussion: 2018 NFPA 70E, Electrical Hazard Analysis

- Hazards related to shock

- Hazards related to arc flash

- Hazards related to arc blast

- Magnitude of hazards – Time and current aspect and impact

- Other secondary injuries – From shock, arc flash, and arc blast

- Hazards related to mechanical and electrical energy in a fault

- Arc flash hazard assessment requirements

- Methodology

- Arc Flash prevention cost

- Mitigation of Electrical Hazards

- Process of prevention

- Data Collection, Power System Modeling, Short Circuit Study, Protective Device Coordination, Arc Flash Calculations, Reporting, Label Installation

- Exercise 9: Find ways in preventing Arch flash hazards in your work environment.

- Exercise 10: Line audit to observe and collect hazard conditions in relation to electrical safety and Arc Flash dangers.

Establishing an Electrically Safe Work Condition

- Electrically Safe Work Condition

- LOTO – Lockout / Tagout program requirements

- LOTO principles and responsibilities

- LOTO equipment requirements

- LOTO procedure requirements

Zero Energy Verification

- What is zero voltage?

- What is zero energy condition in an electric circuit?

- How to ensure zero energy is present in circuit.

- Dos and don’ts for zero energy verification

- Zero energy utility switch: Function, use and testing voltages

- What PPE is required and used during a Zero Energy Verification

Working While Exposed to Electrical Hazards

- What is energized electrical equipment?

- Identify conditions – Working on energized electrical equipment is justified

- Requirements for working while exposed to electrical hazards

- Define the approach boundaries for shock protection

- Arc flash personal protective equipment (PPE) requirements (Incident energy method or Table method)

Personal Protective Equipment

- Identify maintenance requirements

- Overcurrent protective devices

- Flexible electrical cord and cables

- Fuses and circuit breakers

- Electrical equipment in hazardous locations

- Portable electric tools and equipment

- Safety and protective equipment

Safety-Related Maintenance and Special Equipment

- Identify types of personal protective equipment (PPE)

- Purpose, and limitations

- Factors to be considered in selecting proper PPE

- Care and maintenance requirements for PPE

- Selecting tools for work on energized electrical equipment

- Alerting techniques necessary for employee safety

- Special personal protective equipment – Battery room personnel

Conclusion

- Training summary

- Post test assessment

- Training evaluation